Let Escar UK Bronze guide you through the 6,500-year-old Lost Wax Bronze Casting Process employed to create the Hollow Cast Bronze Statues & Sculptures, that we proudly offer for sale in the UK

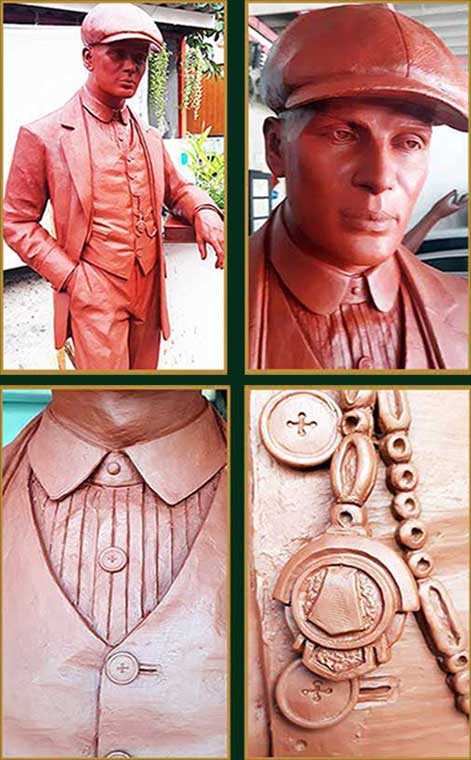

Firstly, creating a realistic and finely detailed bronze sculpture begins with extensive research, starting with a collection of numerous photos of the subject, for reference purposes

Extra special consideration is given to photos that capture the facial expression the artist & commissioner wish to immortalise in the final sculpture

By meticulously studying and selecting these photos, the artist can craft a lifelike and meaningful sculpture, that faithfully represents the subject in bronze

If necessary, a sketch may be produced and presented to the customer for confirmation that this is indeed, an accurate representation of the finished bronze they have in mind

An artist creates a model using materials such as wax, clay or other oil-based substances, that remain soft and workable

We at Escar UK Bronze prefer to use modelling wax as there is no need to fabricate an armature (a framework that supports a sculpture when it can’t stand on its own), as is required with clay

By using various pre-made modelling waxes, the artist has the luxury to customise the hardness of the material according to the project’s needs, simply by mixing various types of waxes, and / or using additives

Also waxes sensitivity to temperature is also a major advantage over clay, as different waxes behave differently, at different temperatures

When cold, modeling wax is hard & rigid and suitable for carving, when warm, it becomes soft and pliable, which is ideal for moulding

It can also be heated in a pot and painted on with a brush to create thin layers or when slightly cooled, applied with a spatula or knife if thicker layers are required

When completely cool, wax is able to capture a higher level of detail that unfortunately, is difficult to obtain with clay

Allowing wax to cool and harden between sessions means a modeling project can be paused and later resumed without drying out, unlike clay. This feature is particularly useful when awaiting feedback on a commissioned sculpture

Another huge advantage of modelling wax against clay is that it can be reused almost indefinitely and if well looked after, is an ideal substrate to rework a concept, many times over

And last but not least, modelling wax can be added or removed with ease

A mould of two shell-like halves is made from the original wax model, with each having two layers, one inner and one outer

The inner layer is normally created using latex or silicone to perfectly capture the fine detail the artist has imparted into the wax, whereas the outer layer is commonly made from plaster or fibreglass, to support and protect the soft mould within

During this process, flanges with built-in male to female register pegs are added on the outside around the middle to facilitate splitting it into two halves when cured, and more importantly, to ensure the two halves match up perfectly when re-assembled

Holes are also drilled around the flange to allow the two halves to be bolted together to prevent any movement, after they have been carefully aligned

When cured, the moulds are then carefully separated to produce two halves and removed from the artist’s wax

This is done as many times as is necessary until the required thickness is achieved, normally around 3mm

The two halves are then carefully re-assembled to become a whole and molten wax is poured inside and swirled around to allow an even layer to coat the inner surface

Every artist is different however and will have found their own preferred quantities of wax to make their ideal cast

It is then allowed to cool, resulting in a hollow wax positive copy of the piece on the inside

The hollow space is then filled with a slurry of silica to give internal support to the wax positive created in the previous process

Once set, the mould is then removed from wax positive and the two halves are put into storage for making duplicates

The positive copy is then “Chased”

Chasing is where a heated metal tool is used to hide any imperfections in the wax positive and to remove the line that is produced by using a mould of two halves

If the bronze needs to be cast as a whole, any additional pieces that were moulded separately would also be added at this point

The positive wax copy is then ‘Sprued’ with a treelike structure of wax rods, that will eventually provide paths for the molten casting material to flow in and for air to escape

The sprued wax copy is then alternately dipped into a slurry of silica and sand stucco, the combination of these two materials being known as the Ceramic Shell Mould

This process is repeated until half an inch of Ceramic Shell Mould coats the wax copy

The next stage is to turn the mould upside down to retain the wax, then fire it in a kiln to harden the ceramic shell, making it strong enough to endure the heat of the molten bronze during casting

Once hard, metal pins are hammered through the outer shell, on though the wax and into the inner core, to keep the inner and outer moulds in alignment once the wax is melted and poured away

It is then brought up to temperature, turned upright to allow the molten wax inside to drain off from the bottom through the sprued vents & tunnels, leaving a hollow space between the inner and outer ceramic moulds for casting

It is at this stage our process gets it’s name, ‘The Lost Wax Bronze Casting Process’

Before the molten bronze is added, the mould will first be tested using water, to find any weak points or holes where leaks may occur

Any damage can then be repaired, holes patched and should they be required, additional holes drilled to aid draining

Now it is secure and strong, the shell is heated once again to remove any remaining moisture, and to bring it up to the temperature of the molten bronze to prevent shattering due to differences in temperature

Our final mould is now ready for casting

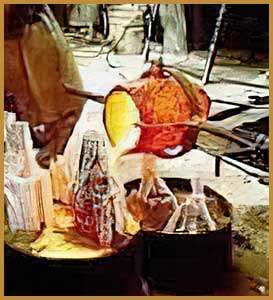

The bronze casting process begins with melting the bronze metal in a furnace, which reaches approximately 1200°C to achieve a molten state

The molten bronze is then transferred to a crucible, both for safety and ease of transport, and poured into the pre-heated mould. Once the mould is filled with the required amount of molten bronze, it is then left to cool and solidify

This careful control of temperature and gradual cooling ensures the final cast maintains its desired shape and structural integrity

The process highlights the importance of temperature management in metal casting, not only to prevent damage but to also to ensure a high-quality final product

When cool, the bronze casting is released by drilling away the inner core, hammering away the outer shell and removing the sprues

The sprues will be melted down and used again but the ceramic shell is lost

Bronze metal chasing is employed, the same as with wax chasing, to remove all signs of casting

Imperfections or pits from air bubbles can be removed by filling the surface and refinishing and where the sculpture has been cast in several pieces, these are welded together and re-finished

Finally we have a finished bronze cast of the original sculpted model, which is then prepared for Patination

This is the art of colouring the sculpture using various chemicals, different combinations of which, create various colours

Once patinated, the sculpture is then protected with layers of wax applied under heat, followed by two cold applications and then buffed to reach a fine lustre

The sculpture is then protected with layers of wax applied under heat, followed by two cold applications and then buffed to reach a fine lustre

Overtime and after repeated use, the definition will be reduced and a new mould will need to be fashioned

Also because of the fragile nature of silicon, sometimes the inner moulds get damaged

This is something we keep a close eye on to ensure that our current moulds produce a finely detailed firing wax, to the quality of the original

If degradation occurs, the current wax is returned to the artist, the lost details reinstated, new moulds are created and the old moulds are scrapped

As can be seen from the narrative above, the Art of Bronze is a very hands-on process that goes through many stages, before the final bronze sculpture is ready for delivery to the customer

We do hope the information contained within has been informative and we look forward to making your acquaintance sometime in the future